Summer Maintenance of Electric Motors: The Ultimate Guide ☀️

Summer arrives, bringing sunshine, vacations, and... temperatures that test the resilience of your industrial machinery. While we seek shade, our electric motors face their most critical season. The relentless heat does not rest and can turn a reliable motor into the source of an unexpected and very costly production halt.

But what if you could anticipate it? A well-executed preventive maintenance plan is not an expense; it is the best investment you can make to ensure your business continuity. This definitive guide will show you, step by step, how to shield your motors against the rigors of summer.

Why is maintenance of motors crucial in summer?

Imagine being forced to run a marathon in the middle of August at noon. That is exactly how your electric motors feel when the ambient temperatures soar. The outside heat adds to the heat they generate from their own operation, forcing them to work under extreme conditions.

This extra effort has direct consequences:

Reduces their energy efficiency: An overheated motor consumes more electricity to do the same work.

Drastically shortens their lifespan: Heat degrades vital components, especially insulations.

Increases the risk of unexpected breakdowns: Unplanned shutdowns during peak season can be devastating for productivity.

In summary, understanding how heat affects electric motors is the first step in protecting them.

Main summer risks for electric motors

Summer brings a combination of factors that act like a perfect storm against your equipment. Knowing them is essential to know where to focus your maintenance efforts.

Overheating: enemy number one

This is the most evident and dangerous risk. There is a devastating rule in motor maintenance: for every 10°C that the operating temperature exceeds the nominal, the lifespan of the winding insulation is reduced by half. The insulation is the motor's protective heart; if it fails, the motor suffers a short circuit and becomes unusable until an expensive repair. Preventing the overheating of an electric motor is therefore your top priority.

The impact of humidity and condensation

The warm summer air holds more moisture. When a motor stops and cools down at night, that ambient humidity can condense inside, on metal surfaces and windings. This condensation causes two serious issues: corrosion in metal parts and a progressive loss of insulation capacity, which can lead to electrical failures.

Summer dust and dirt

Summer is usually a drier and dustier time in many environments. Dust, fluff, sawdust, or any other suspended particles adhere to the motor casing. This layer of dirt acts as an unwanted coat, a thermal insulator that prevents the motor from dissipating heat efficiently, exacerbating the overheating problem.

Summer maintenance checklist for electric motors

Here is your battle plan. Follow this industrial maintenance checklist to carry out a complete and effective summer motor review.

Step 1: Inspection and deep cleaning

A clean motor is a happy and cool motor. Cleaning is the first line of defense and one of the most cost-effective tasks you can perform.

Cleaning casings and cooling fins

The casing of a motor, especially the fins, is designed to maximize contact surface with the air and dissipate heat. With the motor disconnected and locked out, use low-pressure compressed air, non-metallic brushes, and cloths to remove all accumulated dirt, grease, and dust. A clean surface transfers heat to the environment much more efficiently.

Inspection and cleaning of fans

The fan is the motor's active cooling system. If its blades are covered in dirt, its efficiency is drastically reduced. Worse, if a blade is broken, the fan becomes unbalanced, causing vibrations that will damage the bearings. Ensure that the fan is clean, intact, and that the protective cover is unobstructed.

Inspection of junction boxes

The junction box is the nerve center of the motor's electrical system. Open it (with the power cut off) and check that it is completely clean, dry, and that the sealing gasket is in good condition. The entry of dust or humidity here is a recipe for disaster.

Step 2: Review of lubrication

Lubrication reduces friction between moving parts, mainly the bearings. Less friction means less heat generation and less wear.

When and how to re-lubricate the bearings?

The right answer is always in the manufacturer's manual. Too much grease is as harmful as too little, as it can increase the temperature and pressure in the bearings. Follow the recommended operating hours or time intervals. If you have no references, a general guideline is every 2,000-4,000 hours of operation for standard motors.

Choosing the right lubricant for high temperatures

Not all greases are alike. In summer, lubrication of motors at high temperatures requires a product with high thermal stability and a high dropping point. A low-quality grease may liquefy with heat, losing its lubricating capacity and leaving the bearings unprotected. Consult the manufacturer's specifications or a trusted supplier to choose the correct grease for high-temperature conditions.

Step 3: Verification of the ventilation system

The motor can be spotless, but if its environment does not allow it to "breathe," it will overheat just the same.

Ensure unobstructed airflow

It is a common practice to use the spaces around the motors as temporary storage areas. Mistake! Ensure there is a free space of at least 15-20 centimeters around the motor for air to circulate freely. Remove boxes, rags, tools, or any object that may block the airflow.

Check the ambient temperature of the workspace

If the motor is in a small, poorly ventilated machine room, the ambient temperature can be excessively high. Consider improving the overall ventilation of the room with additional exhaust fans or blowers. A cooler environment gives the motor a crucial margin to operate safely.

Step 4: Essential electrical checks

These checks will give you vital clues about the internal health of the motor. Always remember to take maximum safety precautions when working with electrical components.

Measuring voltage and consumption (amperage)

Using a clamp meter, measure the motor's consumption under normal load conditions. Compare this reading with the nominal amperage indicated on the motor's nameplate. A significantly higher consumption may be a symptom of mechanical stress, bearing issues, or impending overheating.

Inspection of connections and tightening of terminals

Vibrations and heating and cooling cycles can cause electrical connections to loosen over time. A loose connection creates high resistance, generating a hot spot that can melt insulation and start a fire. Visually inspect and tighten the terminals of the junction box.

Review of winding insulation

This is a more advanced but crucial test to prevent failures in industrial electric motors. Using a megohmmeter, the insulation resistance between the windings and the casing can be measured. A low value indicates that the insulation is degraded (possibly due to heat or humidity), and the risk of a short circuit is high.

Preventive maintenance plan: prepare your motors before the heat

Don't wait for the thermometer to reach 40°C. A proactive approach is key.

Recommended review calendar

Pre-Summer (May/June): Complete the entire checklist of this guide. Deep cleaning, lubrication, electrical checks.

Monthly (During Summer): Quick visual inspection. Check external cleanliness, look for unusual noises or odors, and ensure that ventilation is not blocked.

Weekly (During Heat Waves): Pay special attention. A simple round to "listen" to your motors can help you detect a change in the sound of a bearing before it fails.

Vibration analysis and thermography as predictive tools

If you want to take your reliability to the next level, consider predictive maintenance of motors.

Thermography: A thermal camera detects hot spots invisible to the human eye, revealing loose connections, cooling issues, or stressed bearings before they fail.

Vibration Analysis: Allows detection of imbalances, misalignments, and incipient failures in the bearings with astonishing precision.

These techniques allow for planning repairs, avoiding emergency shutdowns.

Common mistakes in summer motor maintenance

Sometimes knowing what NOT to do is as important as knowing what to do. These are the common motor failures due to heat caused by negligence.

Ignoring external cleaning

This is the most frequent and harmful mistake. Thinking it’s "just dust" underestimates how that insulating layer can make the internal temperature of the motor soar.

Using improper lubricants

Applying standard grease in a high-temperature environment is like putting water in a deep fryer. It will not fulfill its purpose and may cause more harm than good.

Blocking the motor ventilation

Placing a toolbox "just for a moment" next to the fan's air intake can be enough to start a cycle of overheating on a hot day.

Overloading the motor during peak heat hours

If production planning allows, try to schedule jobs that place a heavier load on the motor during the cooler hours of the day or night. This reduces the total thermal stress.

When is it time to call a professional?

This maintenance plan empowers you to carry out many crucial tasks. However, it is vital to recognize your limits.

You can (and should) do it yourself or have your plant personnel:

Visual and auditory inspections.

External cleaning and fan cleaning.

Verification of lubrication and re-lubrication (if properly trained).

Ensuring the ventilation of the environment.

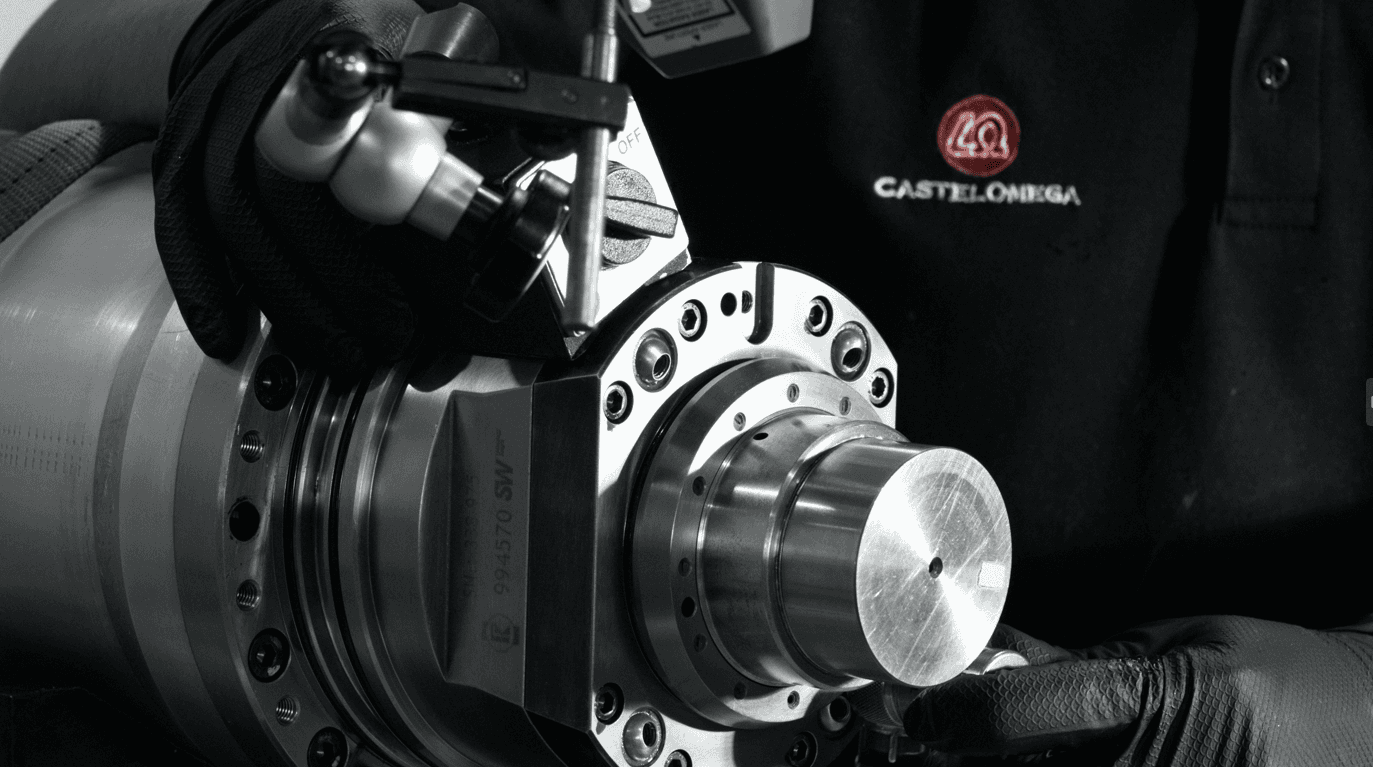

You should call a specialized technician for:

Complex measurements such as insulation resistance with a megohmmeter.

Predictive analysis (thermography, vibrations).

Any internal repair, such as bearing replacement.

Motor rewinding.

Diagnosis of complex electrical failures.

Acting like an expert does not mean doing everything, but knowing when to seek expert help. If you detect an anomaly you cannot resolve, do not hesitate to contact our specialized technical service.

Conclusion: a summer without surprises for your motors

Your electric motors are the muscle of your operation. Treating them with the care they deserve during the year's harshest season is not an option; it is a strategic necessity. By following this guide, you can transform maintenance from a reactive task to a proactive strategy.

A timely cleaning, the right grease, and adequate airflow are simple actions that make a huge difference. Remember: preventive maintenance is not a cost; it is the smartest investment to ensure a summer of maximum productivity and guaranteed reliability. Don’t let the heat halt your production!