Frequency Converter for Industrial Motor: Complete Guide to Selection and Use

In most industrial installations, electric motors have traditionally operated at a fixed speed, with a simple "on/off" switch. This direct starting causes current spikes that stress the electrical grid and mechanical stress that punishes the machinery. But the biggest problem is waste: a motor running at 100% when the application only needs 70% is a constant leak of energy and money.

Fortunately, there is an intelligent solution that completely transforms motor control. The frequency converter (VFD), also known as an industrial inverter or frequency converter, is the key technology that allows you to "dose" energy and control processes with unprecedented precision.

What is a frequency converter and why is it key in modern industry?

A frequency converter is an electronic device that is installed between the power supply and an alternating current (AC) motor to control its rotation speed. Instead of a simple switch, it acts as an intelligent "accelerator" for the motor.

Its operating principle is based on a three-stage process:

Rectifier: Converts the alternating current (AC) from the grid into direct current (DC).

Intermediate Circuit: Stores and filters this direct current.

Inverter: Transforms the direct current back into alternating current, but this time with variable frequency and voltage, thus allowing for a fully adjustable three-phase motor speed control.

Knowing how a frequency converter works is understanding the first step towards more efficient and reliable processes.

Main advantages of using a frequency converter

Implementing a VFD goes far beyond simply being able to adjust speed. The benefits directly impact the profitability and lifespan of the equipment.

Substantial energy savings (Reason #1)

This is the most powerful argument. In variable torque applications like pumps and fans, the savings are spectacular thanks to affinity laws: a small reduction in motor speed produces a cubic reduction in energy consumption. For example, reducing speed by 20% can result in energy savings of almost 50%. In many cases, the savings generated pay for the equipment investment in less than two years.

Precise control of speed and motor torque

A converter allows you to adjust the motor speed to the exact needs of the process. In a conveyor belt, for example, you can synchronize the speed with other parts of the production line, improving the quality of the final product, reducing jams, and optimizing workflow.

Soft starts and stops to protect the mechanics

The frequency converter programs smooth acceleration and deceleration ramps, eliminating the violent current spikes from direct starting and the abrupt mechanical shocks. This translates into:

Less stress on couplings, belts, and gears.

Elimination of the "water hammer" in pumping systems.

Longer lifespan of all machinery connected to the motor.

Although a soft starter also offers this advantage, a VFD goes much further by allowing total control of speed throughout the entire work cycle, something that differentiates it from soft starter vs frequency converter.

Improvement and automation of production processes

Modern converters are intelligent devices that can easily integrate into control and automation systems (PLCs) via field buses. This enables the creation of dynamic and automated processes, where motor speed responds in real time to production variables.

How to select the right frequency converter for your motor

Choosing the right equipment is crucial for the success of the project. Follow these steps to select the ideal frequency converter for your application.

Step 1: Analyze the motor's nameplate characteristics

The first step is to gather the fundamental data from the nameplate of the motor to which it will be connected:

Voltage (V): The converter must be compatible with the motor's voltage (e.g. 230V, 400V).

Rated Current (A): This is the most important data. The converter must be capable of supplying at least the motor's rated current.

Power (kW or HP): Helps in sizing, but current is the decisive factor.

Frequency (Hz): Normally 50 Hz in Europe.

Step 2: Define the application requirements (constant torque vs. variable torque)

This is the most important technical distinction:

Variable Torque Applications: Centrifugal pumps, fans. The needed force (torque) decreases drastically when reducing speed. They require "normal duty" converters (Normal Duty).

Constant Torque Applications: Conveyor belts, elevators, extruders, compressors. The required force remains high even at low speeds. They require "heavy duty" converters (Heavy Duty), capable of withstanding overloads.

Step 3: Consider the working environment

Where will the converter be installed? Ambient temperature, altitude, humidity, and the presence of dust or conductive particles affect its performance. Make sure to choose equipment with the appropriate IP protection rating for the environment.

Step 4: Evaluate additional functions

Braking: If the application requires rapid or controlled stops (e.g. elevators), you may need an external braking resistor.

Communications: If you need to integrate it into a control system, check that it is compatible with your field bus (Modbus, Profinet, EtherNet/IP, etc.).

Safety: Functions such as STO (Safe Torque Off) allow for safe and certified emergency stops.

Keys to proper installation and commissioning

A proper frequency converter installation is as important as its selection.

The importance of cabinet location and ventilation

A frequency converter generates heat during operation. It is essential to install it in an electrical cabinet with sufficient free space around it (above, below, and on the sides) and, if necessary, with forced ventilation to ensure it does not overheat. Heat is the main enemy of electronics.

Cabling and connections: best practices

To minimize electromagnetic interference (electrical noise) that may affect other sensitive equipment, it is highly recommended to use shielded cable between the converter and the motor, with the shield properly grounded at both ends.

Programming basic motor parameters

A converter taken out of the box cannot effectively protect your motor. It is essential to enter the basic frequency converter parameters extracted from the motor's nameplate (voltage, rated current, speed, etc.). This simple step allows the converter to create a thermal model of the motor and protect it against overloads.

Common errors when choosing and installing a frequency converter

Oversizing or undersizing the equipment: One that's too small will fail due to overload; one that's too large is a waste of money and may not adequately protect a smaller motor.

Ignoring harmonics and electromagnetic compatibility (EMC): Converters can generate "noise" in the electrical grid. In sensitive or large installations, it may be necessary to install harmonic filters.

Poor ventilation of the electrical cabinet: This is the most common cause of premature failures due to overheating.

Not configuring motor protections correctly: Leaving factory parameters is like installing a security system without activating it.

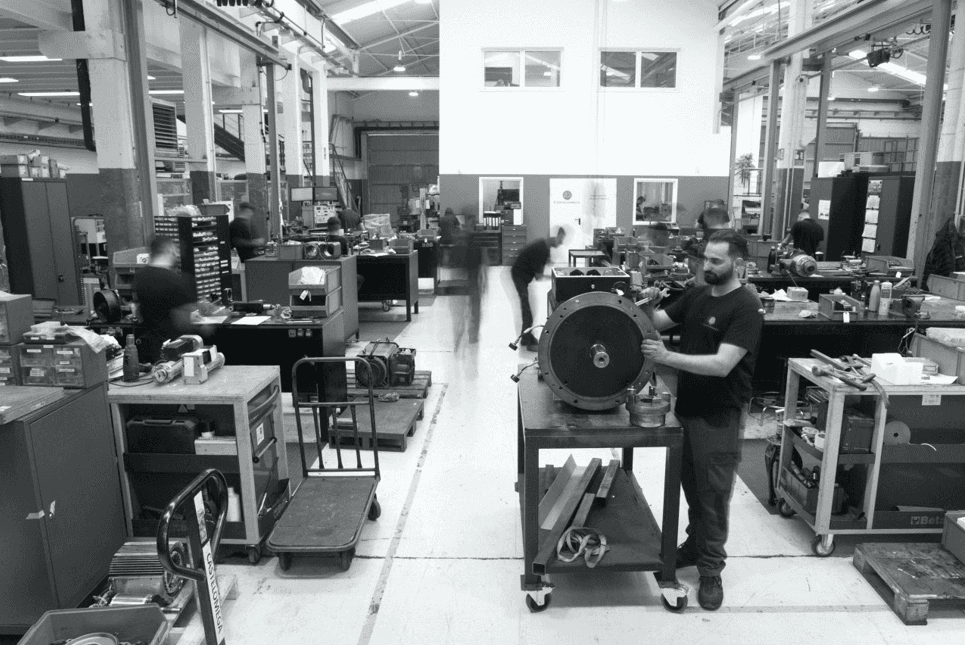

Typical industrial applications of frequency converters

The applications of frequency converters are practically limitless, but some of the most common include:

Pumping systems and water treatment.

Fans and HVAC systems.

Conveyor belts and logistics systems.

Air compressors.

Elevators and cranes.

Extruders, mixers, and lathes.

Do you need advice to select your converter?

As you have seen, selecting and correctly installing a frequency converter involves considering multiple technical factors to ensure optimal and reliable performance. An error in selection can lead to poor performance or premature failures.

If you want to ensure the success of your project and have the perfectly sized equipment for your needs, contact our experts. We offer personalized advice to find the most efficient and cost-effective solution.

Conclusion: Beyond savings, total control over your processes

In short, the frequency converter is one of the smartest investments in modern industry. The impressive energy savings often cover the cost of the equipment, but its true value lies in improving process control, increasing the lifespan of machinery, and greater operational reliability. It is the tool that gives you total and precise control over your motors and, by extension, over your production processes.