Synchronous vs Asynchronous Motors: In-Depth Technical Analysis for Industrial Decision Making

In contemporary electrical engineering, the choice of drive system is a determining factor in the overall efficiency of a plant (OEE). The dichotomy between synchronous and asynchronous motors is not limited to a difference in speed; it directly affects reactive power consumption, the complexity of electronic control, and the lifespan of the asset.

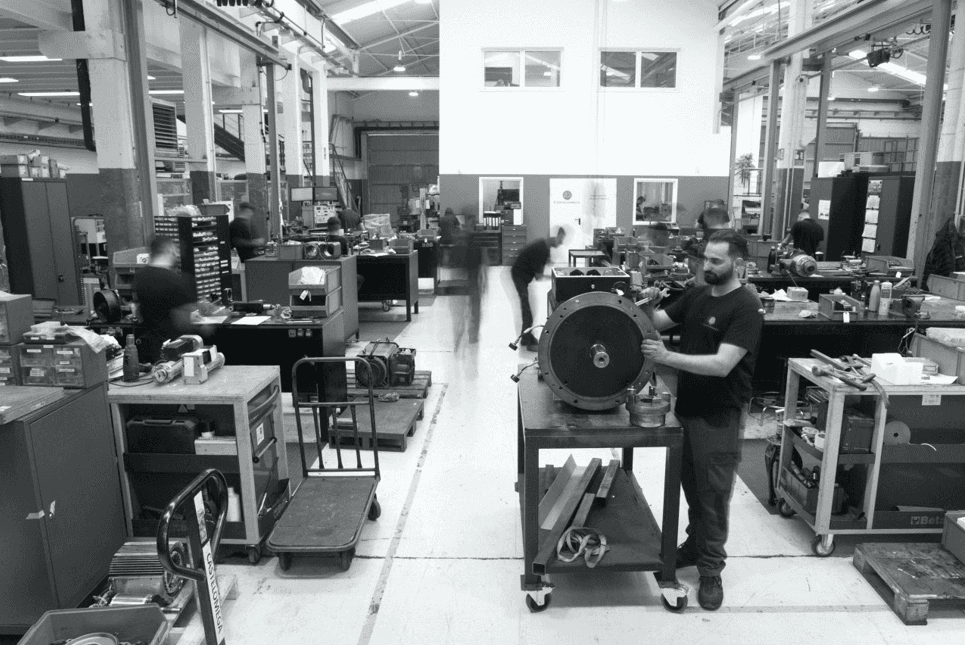

From CastelOmega, as a reference center in the repair of servomotors and electromechanical maintenance, we provide our technical insight into these two fundamental technologies.

1. Electromagnetic Fundamentals: The Nature of Rotation

To understand the differences, we must analyze how torque is generated in each technology.

The Asynchronous Motor (Induction)

The asynchronous motor is based on Faraday's law of induction. The rotating magnetic field of the stator induces a current in the rotor (typically a squirrel cage). This induced current creates its own magnetic field that tries to "follow" that of the stator.

The concept of slip: it is physically impossible for the rotor to reach the speed of the magnetic field (synchronous speed). If it did, there would be no flow variation and, therefore, no torque. That differential is the slip, which usually fluctuates between 2% and 5% under nominal conditions.

The Synchronous Motor

In this design, the rotor has its own magnetic field independent of the stator, whether through permanent magnets (PMSM technology) or windings excited with direct current.

Synchronous speed: the rotor is "locked" magnetically with the stator's field. They rotate in unison. The rotational speed (n) is rigidly tied to the frequency (f) and the number of pole pairs (p) by the formula:

n = (60xf)/p

2. Detailed Technical Comparison: Analysis Dimensions

Efficiency and Energy Performance

The synchronous motor is intrinsically more efficient. By not relying on induction to magnetize the rotor, "copper losses in the rotor" due to the Joule effect are eliminated.

Permanent magnet motors: achieve efficiency ratings of IE4 and IE5, drastically reducing CO2 emissions and the electricity bill in continuous operating processes.

Control and Precision

Synchronous: they are the kings of position and speed control. In robotics and CNC machine applications, the synchronous motor allows for immediate dynamic response.

Asynchronous: although vector control frequency drives (VFDs) have improved their accuracy, they still show slower responses to sudden load changes due to the magnetic inertia of the induction process.

Power Factor

A critical aspect for maintenance managers:

The asynchronous motor always consumes reactive power from the grid to magnetize itself.

The synchronous motor can operate with a unity power factor (1.0) and even act as a synchronous capacitor to correct the installation's power factor, avoiding penalties on the electricity bill.

3. Matrix of Industrial Applications

Application | Recommended Technology | Technical Reason |

Pumping and Ventilation Systems | Asynchronous | Low cost, robustness, and sufficient starting torque. |

Packaging Lines and Robotics | Synchronous (Servomotor) | Need for precise positioning and constant torque. |

High Power Compressors | Synchronous | Maximization of long-term energy efficiency. |

Mills and Crushers | Asynchronous | Capacity to withstand overloads and harsh environments. |

4. Challenges in Maintenance and Repair

In CastelOmega's workshop, we observe that each technology requires a specialized maintenance approach:

Asynchronous Motor Maintenance

They are "hardy" machines. The main focus tends to be:

Monitoring vibrations in bearings.

Cleaning the ventilation channels (key to preventing insulation deterioration).

Verification of insulation resistance and winding continuity.

Synchronous Motor Maintenance (Especially Servomotors)

The complexity increases exponentially:

Synchronization of feedback sensors: adjusting an encoder or resolver requires specific electronic tooling. A phase shift of a few degrees can prevent the motor from starting or cause it to overheat.

Magnet Management: the risk of demagnetization due to overheating is critical. At CastelOmega, we perform back electromotive force (Back-EMF) tests to verify the integrity of the magnets.

5. The Verdict: What is Your Best Investment?

There is no universal winner, but there is a clear trend towards synchronization in processes where energy and precision are critical. However, for general-purpose applications where the initial budget is tight, the asynchronous motor remains unbeatable.

Factors to Consider Before Purchase or Repair:

Duty Cycle: Will it run 24/7? (Choose synchronous).

Environment: Is there high dust or impact risk? (Choose asynchronous).

Need for Stall Torque: Must it maintain a static load? (Choose synchronous).

Need to Optimize Your Drive Systems?

At CastelOmega, we not only repair motors; we optimize your company's productivity. We have the most advanced technology for balancing, rewinding, and parameterizing both synchronous and asynchronous motors of any brand (Siemens, ABB, Fanuc, Yaskawa, among others).

Rely on technical expertise to ensure the continuity of your business.

Request technical advice or repair estimate