Vibration Analysis in Electric Motors: The Definitive Technical Guide to Avoid Unscheduled Downtime

In today’s industrial environment, the reliability of assets is the factor that determines the profitability of a plant. Electric motors are the components that drive the industry, but they are also susceptible to mechanical and electrical failures that, if not detected in time, can lead to astronomical repair costs.

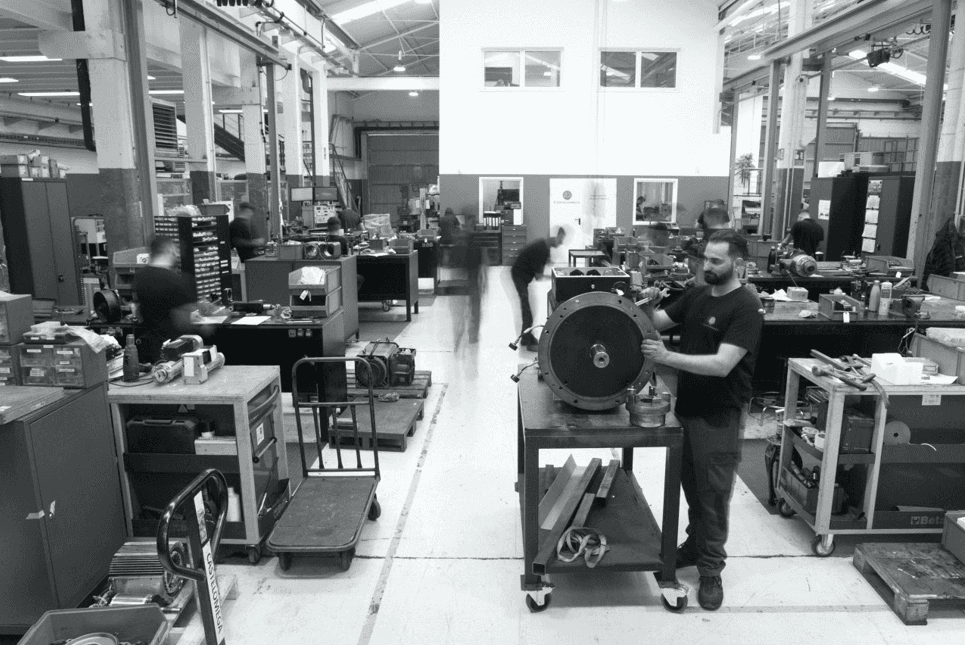

At CastelOmega, with decades of experience in the repair and maintenance of electromechanical systems, we understand that vibration analysis in electric motors is not just a measurement technique, but the fundamental pillar of a world-class predictive maintenance strategy.

What is vibration analysis and how does it work?

Vibration analysis involves the acquisition and study of the mechanical oscillation signals of a machine. Each rotating component of a motor generates a specific frequency. When a component starts to degrade, its vibration signature changes.

Using accelerometers and spectrum analyzers, we transform a complex signal in the time domain into a representation in the frequency domain, known as FFT (Fast Fourier Transform). This allows us to "see" inside the motor without the need to disassemble it.

Why is it the preferred method in the industry?

Unlike thermography or oil analysis, vibrations offer a much wider window of detection. We can identify a fault in a bearing up to 6 months before it leads to failure.

Main Pathologies Detectable Through Vibration Analysis

To position oneself as an authority, it is crucial to understand that not all vibrations indicate the same problem. Here are the most common diagnoses we perform in our workshop:

1. Mass Imbalance (Unbalance)

This is the most frequent problem in rotors. It occurs when the center of gravity does not align with the axis of rotation.

Symptom: high vibration at the rotation frequency (1X RPM).

Consequence: premature bearing fatigue and damage to the shaft.

2. Misalignment

This occurs when the motor shaft and the coupled load shaft are not concentric or have an angle between them.

Symptom: elevated peaks at 1X and 2X frequencies, especially in the axial direction.

3. Mechanical Looseness

This can be structural (weak motor base) or internal (loose fits between parts).

Symptom: appearance of multiple harmonics of the rotation frequency in the spectrum.

4. Bearing Defects

Bearing failures are the critical failure points. Through envelope analysis, we detect failures in:

Inner race (BPFI).

Outer race (BPFO).

Rolling elements (BSF).

Cage (FTF).

5. Eccentricity and Electrical Problems

These are often confused with mechanical problems. A varying air gap or broken rotor bars generate magnetically induced vibrations that only an expert can differentiate from a mechanical imbalance.

The Professional Analysis Protocol at CastelOmega

It is not enough to just place a sensor; the quality of the data is everything. Our process follows international standards such as ISO 10816 and ISO 20816:

Measurement Point Audit: we mark fixed points on the bearing housings (vertical, horizontal, and axial) to ensure data repeatability.

fmax and Resolution Lines Configuration: we adjust the analyzer according to the motor's RPM to avoid losing details at high frequencies.

Trend Analysis: we compare current data with the historical data of the motor. An absolute "low" value can be dangerous if it has increased by 50% in a week.

Diagnosis and Prescription: we provide a technical report that classifies the severity of the fault and recommends the necessary action: monitor, schedule repair, or immediate shutdown.

Competitive Advantages of Implementing Predictive Maintenance

Investing in periodic analysis of your electric motors offers immediate return on investment (ROI):

Factor | Reactive Maintenance (Failure) | Predictive Maintenance (CastelOmega) |

Repair Cost | Very high (emergency repairs) | Optimized (planned repair) |

Availability | Long unforeseen downtimes | Minimal planned downtimes |

Motor Life | Reduced due to mechanical stress | Maximized |

Safety | Risk of catastrophic failures | Controlled environment |

Why Choose CastelOmega for Your Vibration Analysis?

At CastelOmega, we are not just data collectors; we are precision engineers and mechanics. Our advantage lies in vertical integration:

Specialization in Servomotors: while others only analyze standard induction motors, we are leaders in diagnosing complex servomotors and high-speed motors.

Responsiveness: if the analysis detects a serious problem, we have the most advanced mechanical and winding workshop to solve the issue without intermediaries.

Executive Technical Report: we speak your language. Our reports are clear, direct, and oriented towards managerial decision-making.

Conclusion: Take Control of Your Industrial Plant

The vibration analysis in electric motors is the ultimate tool to eliminate uncertainty in your production processes. Don’t let a bearing worth a few euros stop a production line worth millions of euros.

Do you want to schedule a technical inspection or a vibration route at your facilities?

At CastelOmega, we are ready to be your technological partner.

Contact our expert technicians or call us directly for a personalized consultation.