Recovery of geometry of the HSK-A63 cone in an IBAG brand electric spindle

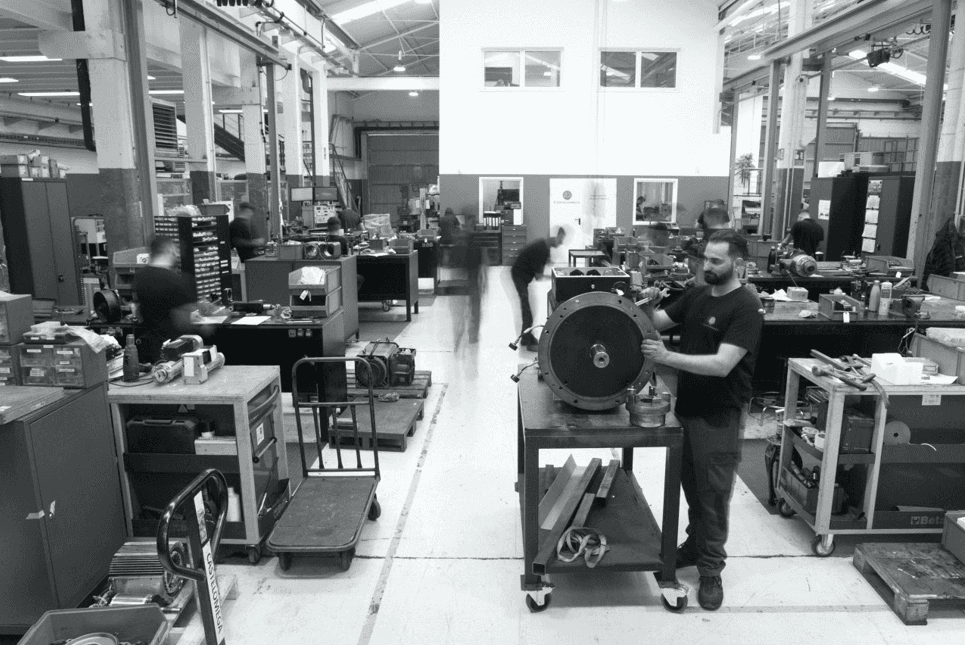

At CastelOmega, we encountered an IBAG electric spindle that had a radial jump of 0.011 mm in the interior of the cone. To restore its original precision, we applied a customized technical solution.

We used laser welding to recover the surface and subsequently ground the area to ensure a perfect fit of the HSK-A63 cone.

A clean, precise, and efficient process that allows us to maintain the highest standards of quality and functionality.

Technology and precision at the service of industrial performance.