Specialized Technical Assistance Service (SAT) for Electric Motors

In the industry, a halted motor is not just a mechanical problem; it is a direct financial loss. Every minute of unplanned downtime affects your bottom line. Our Technical Assistance Service (SAT) is designed with a single priority: to minimize downtime and quickly restore operation to your plant with maximum speed and technical guarantees.

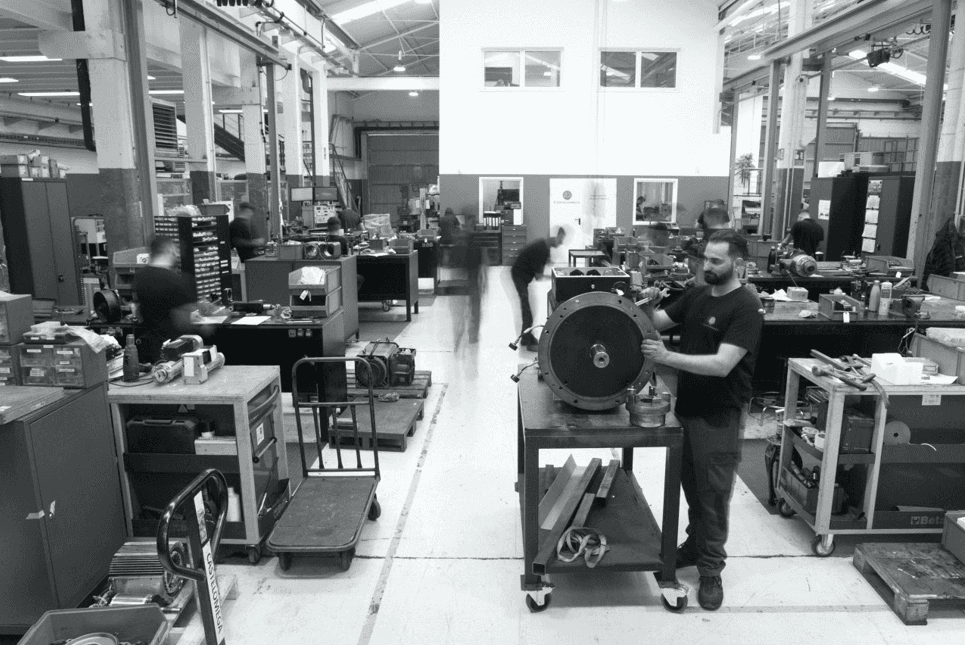

Whether through an urgent intervention at your facilities or a complete overhaul at our electromechanical workshop, we offer solutions for the complete lifecycle of your rotating machines.

Comprehensive Assistance Solutions for Industrial Motors

We understand that not all breakdowns require the same solution. We adapt our technical response to the severity of the failure and the logistics of your plant.

Corrective Repair and Rewinding in Workshop

For critical failures that require significant disassembly, we have facilities equipped for total reconstruction. This process includes:

AC/DC Motor Winding: replacement of burned or degraded windings, using class H or higher insulation materials.

VPI Varnishing (Vacuum and Pressure Impregnation): essential for ensuring dielectric strength and thermal dissipation, superior to simple immersion varnishing.

Precision Mechanics: recovery of bearing housings and dynamic balancing of rotors to eliminate future vibrations.

On-site Technical Assistance

If the motor is too large to be transported or the problem lies in the installation, our team will come to you. We perform:

Laser Shaft Alignment: we correct misalignments between the motor and load (pumps, reducers) that destroy couplings.

Vibration Diagnosis: spectral analysis to identify whether the fault is with the bearings, imbalance, or mechanical looseness without stopping the machine.

Replacement of bearings and brushes on-site.

Remote Support and Diagnosis 4.0

Through monitoring systems, we can advise your maintenance team on abnormal parameters in drives or sensors, helping decide whether it is necessary to stop the machine before a catastrophic failure occurs.

When to Request Urgent Technical Intervention? Critical Symptoms

Ignoring the first "whines" of a motor often turns a minor industrial corrective maintenance issue into an expensive replacement. Act immediately if you detect:

Abnormal Vibrations and Excessive Noise

A vibration that gradually increases will not fix itself. It usually indicates an imminent failure in the bearings, rotor imbalance, or severe misalignment. If the noise changes tone or intensity, the mechanical integrity of the equipment is compromised.

Overheating and Triggering of Protections

If the motor is hot to the touch or repeatedly trips thermal protections, do not force the reset. You may be facing a ventilation issue, mechanical overload, or an impending insulation failure. Forcing it in this state will cause an irreversible short circuit.

Our Protocol: From Diagnosis to Startup

Transparency is the foundation of our technical trust. We do not improvise; we follow a strict workflow:

Reception and Disassembly: equipment registration and controlled disassembly to avoid hiding evidence of the root cause.

Cleaning and Decontamination: removal of grease, dust, and debris through dielectric washing or ultrasound.

Diagnostic Testing: we apply shock wave tests (surge test) to assess the health of the winding and micrometric measurements of the shafts.

Report and Estimate: you will receive a detailed technical report with the cause of the breakdown and a firm estimate. No surprises.

Repair and Final Testing: after the repair, the motor goes to the test bench. We conduct vacuum and load tests to certify that it meets the nominal values before delivering it to you.

Checklist: What to Check Before Calling Technical Service

We want to be your efficient partner, not charge you for avoidable visits. Before requesting urgent assistance, ask your maintenance team to check these basic points:

[ ] Input Voltage: Are the three phases reaching the junction box with the correct voltage? (Rule out blown fuses upstream).

[ ] Mecanical Lock: Does the shaft turn freely by hand (if it is safe to do so)? Sometimes the pump or fan is jammed, not the motor.

[ ] Protections: Has the thermal relay tripped? Check if it is properly set to the rated current of the plate.

[ ] Connections: Are there loose or burned wires in the junction box?

If the problem persists after these checks, call us immediately.

Benefits of a Maintenance Contract vs. On-Demand Assistance

On-demand assistance solves the problem, but a maintenance contract prevents it. Transitioning from a reactive to a preventive model offers clear advantages:

Reduction in Downtime: we detect faults months before they shut down the line.

Priority in Assistance: guaranteed response within agreed times (SLA) in emergencies.

Predictable Costs: avoids emergency repair bills, which are usually higher due to urgency and express transport.

Stock Management: we help you define which critical original spare parts you should have in your warehouse.

Frequently Asked Questions about SAT (FAQ)

What brands and power ratings of motors do you service?

We are a multi-brand technical service. We work with leading manufacturers (Siemens, ABB, WEG, Leroy Somer, etc.) and have the capacity to manage everything from small servomotors to large medium-voltage motors of several megawatts.

Do you offer a warranty on the repairs performed?

Yes. All our complete repairs (like a rewinding) include a warranty on labor and replaced materials, ensuring that the motor is in conditions equivalent to a new one.

Conclusion

The reliability of your plant depends on the health of your motors. Do not leave your critical assets in the hands of amateurs.

If you need an agile, expert, and technically advanced technical assistance service, contact us. Whether for a 24/7 emergency or to plan your next technical stop, we are ready to reactivate your production.