Thermography with IoT for motors: the predictive maintenance 4.0 guide

Imagine the scene: it’s the highest production day of the month, the machinery is running at full capacity, and suddenly, a critical motor stops. The silence on the production line is deafening, and every passing minute translates into economic losses. This scenario, all too familiar in the industry, is the result of a maintenance model that no longer has a place in today’s environment.

What if your motors could alert you that something is wrong weeks before it happens? That is the promise of thermography with IoT, a technology that doesn’t rely on fixed calendars or intuition, but on real data. It is the ability to listen (and see) what your assets feel, 24 hours a day, to act just in time.

Reactive maintenance is dead: welcome to the predictive era

For decades, industrial maintenance has followed two paths: reactive ("fix it when it breaks") or preventive based on schedules ("change the oil every 5,000 hours"). Both models are inefficient. The first is costly and chaotic; the second often involves changing parts that are still in good condition, or worse, it does not prevent failures that occur between inspections.

We are in a paradigm shift. Predictive maintenance 4.0 does not ask "when was the last inspection?" but "what is the state of the machine right now?" It is the transition from uncertainty to certainty, from reaction to anticipation.

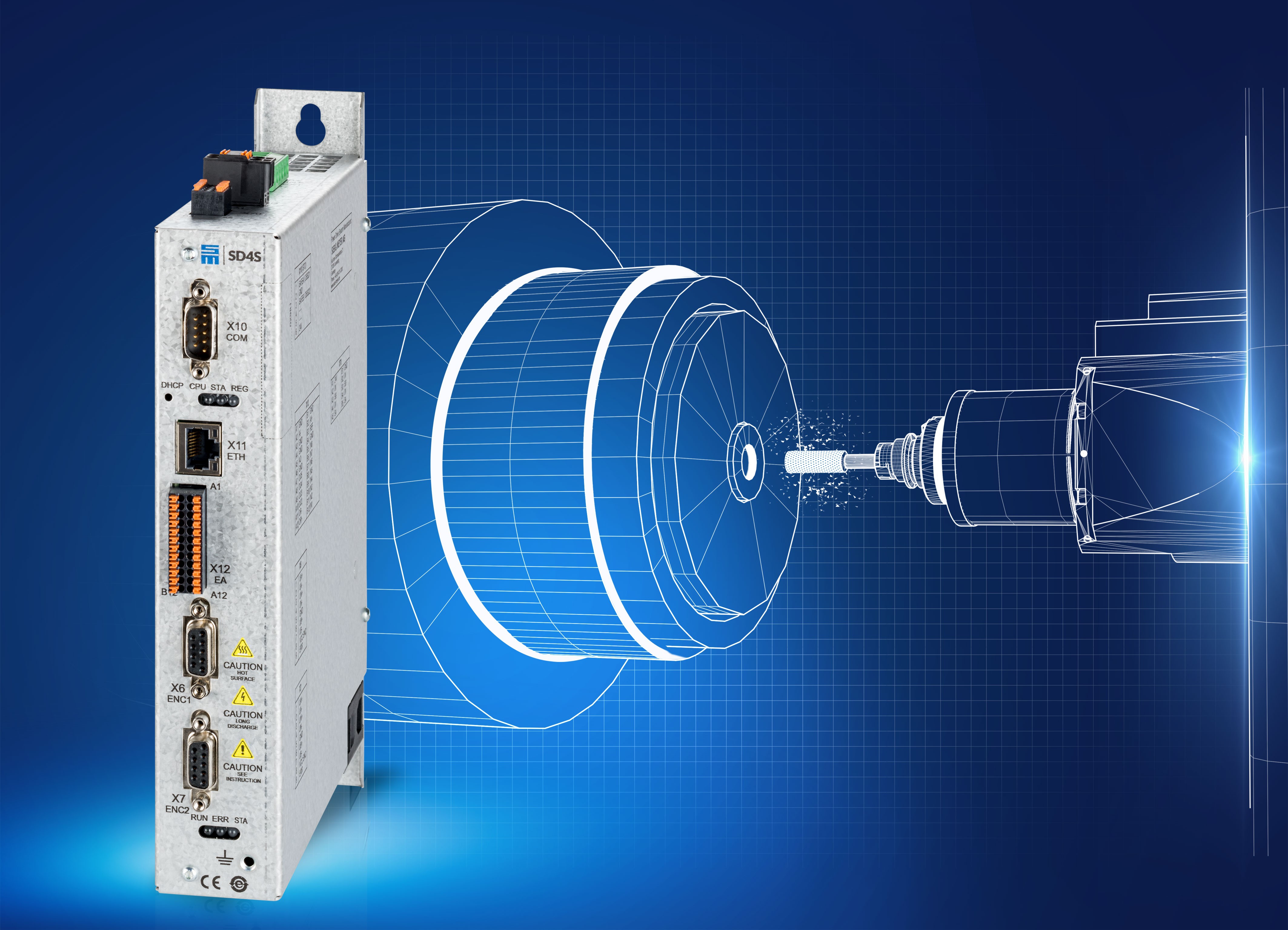

Breakdown of the technology: what is thermography and IoT?

To understand this revolution, we must know its two protagonists.

Thermography: seeing heat to detect problems

Almost any problem in a motor, whether mechanical or electrical, generates heat before it turns into a catastrophic failure. A loose electrical connection, a worn bearing causing friction, an overload… all of these raise the temperature. Thermography is the technology that allows us to see these heat signatures, invisible to the human eye, turning temperature into an image that tells us exactly where the problem is.

IoT (Internet of Things): connecting assets to get data

The Internet of Things (or IoT) is simply a network of physical devices (sensors) that are installed on your machines. These sensors continuously collect data (temperature, vibration, consumption) and send them through the internet to a central platform for analysis. Essentially, the IoT gives your motors a voice to communicate their health status in real time.

IoT thermography for motors: how does the synergy work?

This is where the magic happens. The combination of thermography and IoT creates an autonomous and intelligent monitoring system.

Fixed thermal sensors and continuous monitoring

Unlike a manual inspection with a portable thermal camera that is done once a month, this technology uses temperature sensors for motors or fixed thermal cameras. These devices are permanently installed pointing at the critical points of the motor (bearings, windings, junction box) and perform remote motor monitoring continuously, 24/7.

Real-time data transmission to the cloud

Every few minutes, the sensor measures the temperature and sends that information through a gateway (a device that acts as a bridge) to the internet. The data travels securely to an industrial IoT (IIoT) platform in the cloud, where it is stored and processed.

Analysis platforms and automated alerts

This is the brain of the operation. The cloud software not only displays a temperature graph. It performs a continuous thermographic data analysis, learning what is the normal behavior of the motor. If it detects a temperature rise that is outside safe parameters, it automatically sends an alert to the mobile phone or email of the maintenance team, indicating which motor needs attention and what the anomaly is.

Key benefits of implementing IoT thermography in your motors

The adoption of this technology translates into direct and measurable competitive advantages.

Early detection of anomalies 24/7

Constant monitoring allows the detection of emerging problems that would otherwise go unnoticed between manual inspections, giving you crucial reaction time to plan the intervention.

Drastic reduction of unplanned downtimes

This is the greatest economic benefit. By preventing failures in electric motors, you avoid production halts, protecting your revenue and your customers' trust.

Optimization of maintenance resources

Your technical team will stop wasting time on routine inspections on healthy machines. Thanks to the alerts, they can focus their efforts, time, and resources only on the assets that really need it.

Increased safety and lifespan of motors

A motor that operates constantly within its optimal temperature range suffers less stress and wear, which prolongs its lifespan. Additionally, the risk of electrical failures that could lead to fires or workplace accidents is reduced.

Components of a thermographic monitoring system with IoT

Implementing this solution involves the combination of three fundamental elements:

Fixed thermal cameras vs. spot sensors

Spot sensors (pyrometers): Measure temperature at a single point. They are more economical and ideal for monitoring a specific component, such as a bearing.

Fixed thermal cameras: Provide a complete thermal image of the motor, allowing detection of hot spots in any area. They are the most comprehensive solution for critical motors.

Gateways and connectivity (WiFi, LoRaWAN, 4G/5G)

The data needs a path to travel. The choice of connection technology depends on the environment: WiFi for plants with good coverage, LoRaWAN for long distances and low consumption, and 4G/5G for remote locations without local network infrastructure.

The software: the brain of the system (dashboard and analytics)

The hardware only collects data; the software gives it value. A good platform must offer an intuitive dashboard to visualize the status of all your machinery, analytical tools to understand trends, and a flexible and customizable alert system. This is where the true condition analysis of the machinery takes place.

Practical applications and use cases

This technology is not science fiction, it is already being applied in:

Critical motors in industrial production lines: Where a halt can cost thousands of euros per hour.

Pumping and ventilation (HVAC) systems in large buildings: Essential to ensure comfort and energy efficiency.

Motors in hard-to-reach or hazardous environments: Allows monitoring of equipment without risking personnel.

Steps to implement an IoT thermography project

The digitalization of maintenance may seem complex, but it can be broken down into a clear roadmap:

Initial audit and selection of critical motors

It’s not necessary to monitor everything. Start by identifying the motors whose failure would have the greatest impact on production, safety, or costs.

Designing the system architecture

The appropriate type of sensor is chosen for each motor, the connectivity technology, and the software platform.

Installation and commissioning

The technical staff installs the sensors and gateways, and sets up the initial alerts on the platform.

Training the maintenance team

The staff is trained to understand how to interpret the data from the dashboard and how to react to alerts.

Common mistakes to avoid in your remote monitoring strategy

To ensure the success of your project, be careful not to fall into these common traps:

Choosing low-quality sensors

Cheap can be expensive. An imprecise or unreliable sensor will generate false data and undermine confidence in the system.

Ignoring the importance of good connectivity

A system with state-of-the-art sensors is useless if the data does not consistently reach the platform.

Not correctly defining alert thresholds

If the thresholds are too sensitive, the team will receive false alarms and will end up ignoring them. If they are too lax, the alert may come too late.

The future: AI and Machine Learning in predictive thermography

The next step is already here. The most advanced systems incorporate Artificial Intelligence (AI) and Machine Learning. These algorithms not only alert when a fixed temperature is exceeded but learn the unique thermal behavior of each motor under varying loads and environmental conditions. They can detect subtle deviations and complex patterns that anticipate a failure with even greater accuracy.

Conclusion: transform your maintenance with data, not intuition

Leaving the health of your critical motors to chance or intuition is too risky a bet in industry 4.0. Thermography with IoT offers you a clear and continuous view, transforming your maintenance into a strategic advantage. It allows you to optimize resources, maximize the availability of your equipment, and most importantly, sleep peacefully knowing that you have an tireless guardian watching over the heart of your operation.

Are you ready to stop repairing and start predicting? Request a consultation with our experts and we will assess how this technology can be implemented in your facilities.