Every measure counts. Every data point, too.

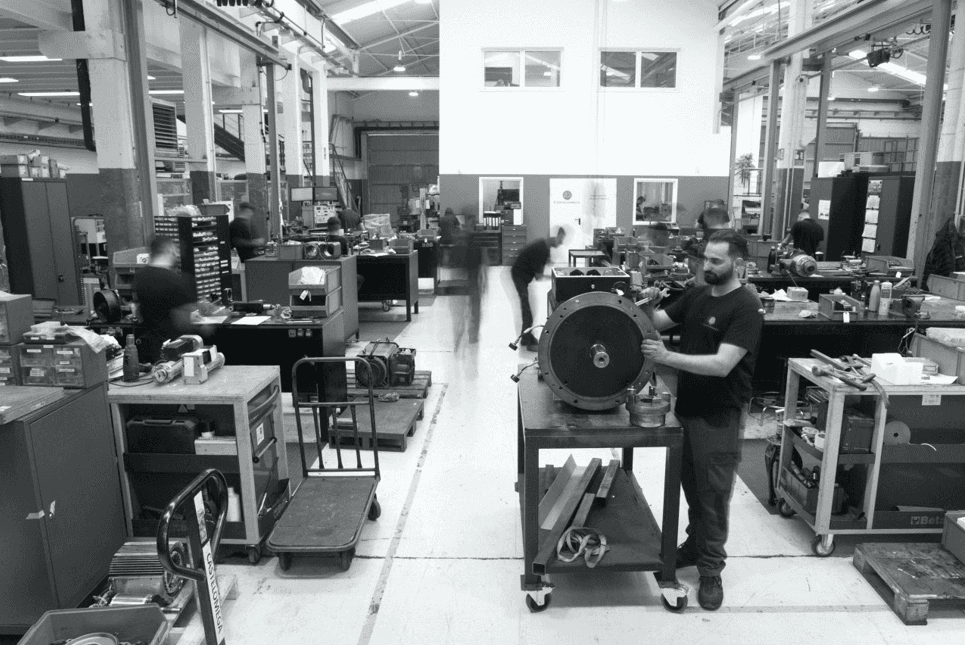

At CastelOmega, we leave nothing to chance. In the image, one of our technicians is taking real-time measurements during the testing of a head in the test bench. This process allows us to verify key parameters such as concentricity, vibration, and the dynamic behavior of the head under controlled conditions.

These measurements provide us with critical information to confirm that the assembly is correct, that there are no deviations beyond tolerance, and that the head is ready to operate with complete precision.

Moreover, this data is documented and stored to trace the technical history of the component, allowing us to detect patterns, prevent future breakdowns, and optimize future interventions.

Because with every repair, we not only restore performance but also generate knowledge.

#PrecisionHead #TestBench #IndustrialMaintenance #DimensionalControl #TechnicalTraceability #CastelOmega