Test benches for frequency converters: validation and load testing guide

In industrial power electronics, uncertainty is unacceptable. Delivering a repaired converter without subjecting it to real stress is like playing Russian roulette with the client's production. A converter may start perfectly on the workshop table but fail within five minutes of moving a conveyor belt under load.

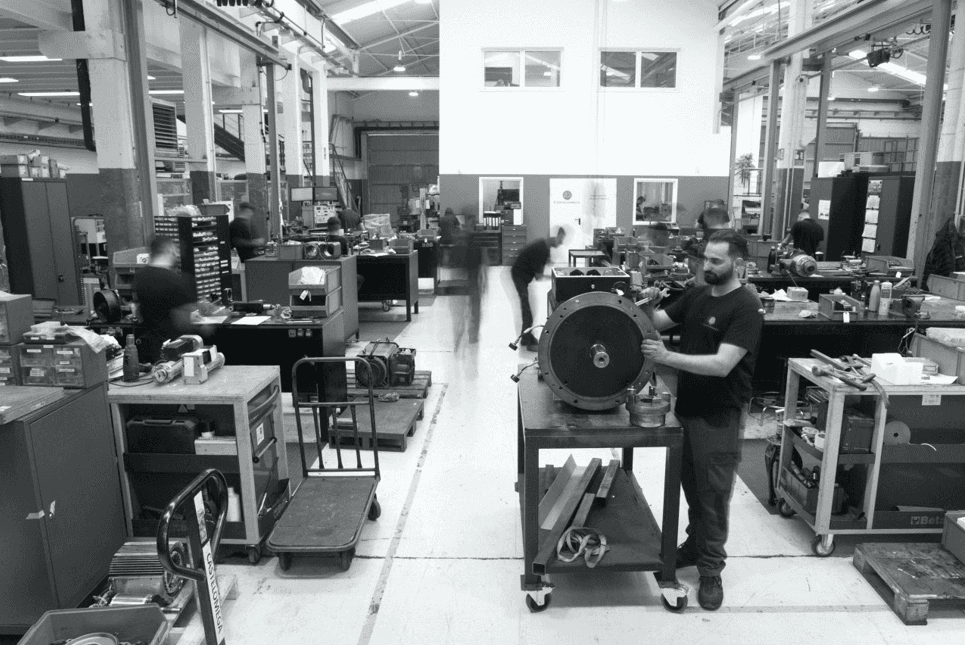

To ensure the reliability of a repair or validation, it is essential to have a well-designed test bench for frequency converters. In this engineering guide, we break down the architecture, the loading systems, and the safety protocols necessary to simulate the harshest conditions of the plant within the laboratory.

What is a test bench for converters and why is it essential?

A test bench is not simply a three-phase power outlet. It is a controlled ecosystem designed to simulate the actual working conditions of the factory (torque, temperature, acceleration) in a safe environment.

Its main function is to validate that the power stage of the equipment (rectifier, DC bus, and inverter) can handle the nominal current without suffering thermal drift or unexpected trips. Without this, any repair is just a hypothesis.

The difference between "starting" and "load testing"

Many technicians make the mistake of validating equipment simply because it "lights up the display" and moves a small motor without load. This is insufficient.

No-load testing: only verifies the control logic and pre-charge.

Load testing: subjects the IGBT modules and the DC Bus capacitors to their nominal current.

It is in this scenario that latent failures arise: cold solder joints that open due to thermal expansion, miscalibrated current sensors, or dry capacitors that do not filter ripple under demand.

Architecture and key components of a professional test bench

To build or acquire a competent system, we must understand its fundamental blocks.

Power supply system (AC/DC input and isolation transformers)

Safety and power quality begin here. It is vital to use a galvanic isolation transformer at the input. This not only protects the operator but also allows connecting oscilloscope probes without the risk of short-circuiting the ground with a phase or the DC bus. Additionally, a variable DC source should be available to feed the bus directly in case of failure in the rectifier stage.

Load motor (dyno) and generating resistant torque

Simply connecting a free motor is not enough. To simulate load, we need a dynamometric system.

Typically, two motors are coupled by the shaft:

Motor under test (DUT): controlled by the converter we are repairing.

Load motor (brake): acts as a generator, opposing resistance to rotation.

By controlling the torque of the load motor, we force the test converter to inject more current to maintain speed, generating real motor torque.

Energy management: braking resistors vs. regenerative units

When the load motor acts as a generator, it produces electricity. What do we do with it?

Resistive load: energy is dissipated as heat through large banks of resistors. It is cheap but inefficient and heats up the workshop.

Regenerative load bank: uses a regenerative unit to return that energy to the workshop's electrical grid. It is the most advanced and sustainable solution ("green testing").

Instrumentation: oscilloscopes and power analyzers

To see the invisible, we need:

Isolated channel oscilloscope: essential for measuring the firing voltage on the gates of the IGBTs (which float at high potential) and verifying the quality of the PWM (pulse width modulation).

Power analyzer: to measure efficiency, power factor, and input/output harmonics.

Standard testing protocol for VFDs (step by step)

A rigorous process always follows this order to minimize risks.

1. Static tests (diodes and IGBTs)

Before applying voltage (cold check), we use the multimeter in diode mode. We check the input rectifier bridge and the output IGBTs for shorts or open circuits. We also perform an insulation resistance test (Megger) on the test motor and, with caution, on certain parts of the converter (never on the control electronics).

2. No-load testing and communication verification

We power the converter. We check that the DC bus pre-charge works (the voltage rises smoothly). We check fans, display, and digital inputs/outputs. We start the motor without load to check that there is rotation and that the three phases are balanced in voltage.

3. Dynamic full load testing and temperature

This is where the real testing starts.

We gradually increase the resistant torque with the dyno until we reach the nominal current of the converter.

We monitor the temperature of the heatsink with a thermal camera.

We check the symmetry of the output currents with the oscilloscope. An asymmetry under load usually indicates a defective firing driver or a degraded IGBT.

4. Verification of protections and firing

We force limit situations (such as momentary overcurrent or loss of input phase) to ensure that the converter detects the fault and protects itself before burning out. We also check the carrier frequency; if increasing it causes the converter to overheat excessively, there may be problems with the snubber filters or the switching speed of the IGBTs.

Types of benches: passive (brake) vs. active (regenerative)

Characteristic | Passive bench (eddy current brake / resistors) | Active bench (AC/AC regenerative) |

Initial cost | Low / Medium | High |

Energy efficiency | Very low (everything turns into heat) | High (recovers up to 90% of energy) |

Torque control | Good, but limited to low RPM | Excellent across the entire range (4 quadrants) |

Complexity | Low | High (requires network synchronization) |

Ideal use | Small workshops or sporadic testing | High-volume labs and engineering |

Safety in the high voltage test laboratory

Working with converters involves deadly risks (400V, 690V, and DC buses of up to 800V).

DC bus discharge: never handle the equipment until measuring that the bus voltage has fallen below 50V. Capacitors can hold lethal charges for minutes.

Isolation: dielectric floor and use of PPE (gloves, glasses).

Emergency stop: the bench must have an accessible emergency mushroom button that cuts off the main power and immediately releases the mechanical load.

Frequently Asked Questions (FAQ)

Why does a converter work with no load but fails in the field?

This is usually due to factors that were not simulated in a basic test: thermal stress under load (expansion of components), vibrations, or external problems like very long motor cables (which generate voltage spikes due to reflected waves) or harmonics in the client's network.

Is it necessary to test the converter with its original motor?

It is not strictly necessary if your test bench has a pattern motor with similar characteristics (power and voltage). However, for closed-loop applications with encoders, it is advisable to have the client's motor to adjust the speed loop torque.

Conclusion

A test bench for frequency converters is the investment that distinguishes a "parts changer" from a professional electronic engineering service. The ability to simulate resistive vs inductive load and thermal stress ensures that when the equipment returns to the plant, it will work on the first try.

Implementing regenerative load protocols and PWM waveform analysis not only saves energy but also provides the technical certainty needed to offer extended warranties on critical equipment.